KLOZURE® Oil Seal

Coping with Demanding Conditions

With or without a metal case, special garter spring or finger spring and in a broad range of materials ideally adapted to all sorts of operating conditions – the result of decades of experience that Garlock has accumulated in this field – our KLOZURE® oil seals are the preferred choice worldwide.

Garlock’s KLOZURE® seals can handle extreme operating conditions – from small devices right through to very heavy machinery. For more than 60 years KLOZURE® seals have been used with great success worldwide in the pulp and paper industry, aluminum and steel industries. KLOZURE® seals, with their carefully selected materials and user-friendly design, combine high functional reliability with long useful life. The extensive KLOZURE® range has repeatedly provided the ideal solution for a wide variety of customer specific applications – not only for new systems but also providing alternatives to plant upgrades.

KLOZURE® Oil Seals with metal case

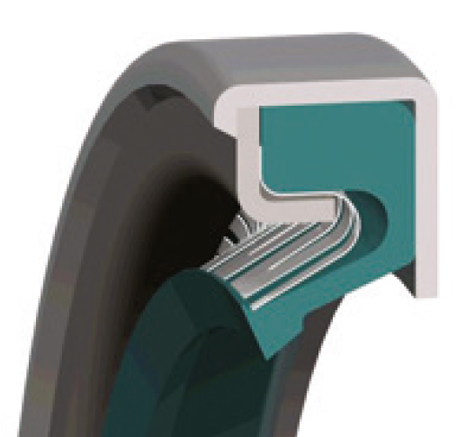

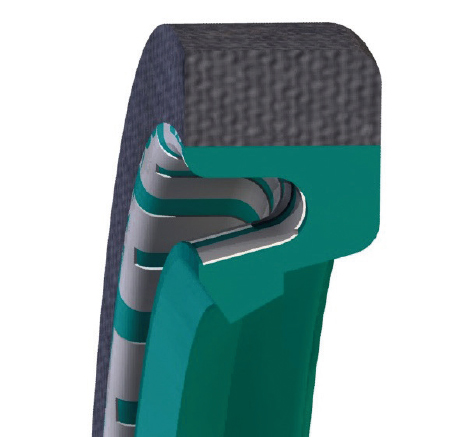

KLOZURE® Model 53

Garlock’s KLOZURE® 53 is a general purpose assembled seal. Within the range of applications for which it is intended (large diameters) this seal offers the best advantages, functionality, reliability and performance. It comes with a heavy-duty metal outer case and is available in single and dual lip configurations.

Features & Benefits

- Heavy-duty metal outer case

- Single and dual lip configurations available

Specifications

- Case: steel*

- Spring: Stainless steel finger spring

- Shaft Diameters (mm): 76,2 – 1524,0

- Maximum Shaft Speed (m/s):

5,0

10,2

15,2 - Maximum Shaft Misalignment and Runout (mm):

0,38

0,25

0,13 - Available Lip Material:

MILL-RIGHT® N,

MILL-RIGHT® ES,

MILL-RIGHT® V,

Silicone

*other materials are available on request (Plunge grinding required).

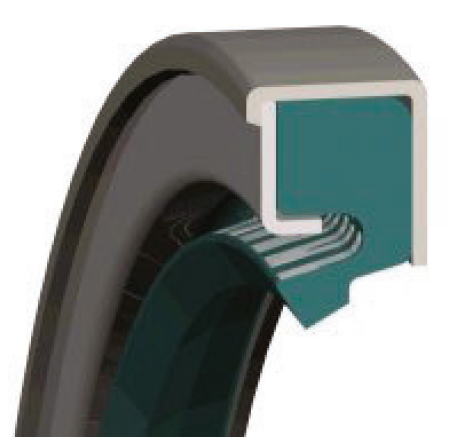

KLOZURE® Model 59

Garlock’s KLOZURE® 59 successfully combines quality with special assembly and installation advantages. KLOZURE® 59 operates with a vulcanized finger spring only. Thanks to its structural design the KLOZURE® 59 is easy to install – even when blind-mounting is necessary. The KLOZURE® 59 is available for shafts of 152,4 mm diameter up to 1778 mm. The bevel lip design prevents lip rollover

Features & Benefits

-

Heavy duty metal outer case

-

Reverse bevel lip design prevents lip rollover

-

Aggressive shaft to bore misalignment capability

Specifications

- Case: steel*

- Spring: Bonded in stainless steel finger spring

- Shaft Diameters (mm): 152,4 – 1778,0

- Maximum Shaft Speed (m/s):

12,7

25,4 - Maximum Shaft Misalignment and Runout (mm):

2,36

1,19 - Available Lip Material:

MILL-RIGHT® N,

MILL-RIGHT® ES,

MILL-RIGHT® V,

Silicone

*other materials are available on request (Plunge grinding required).

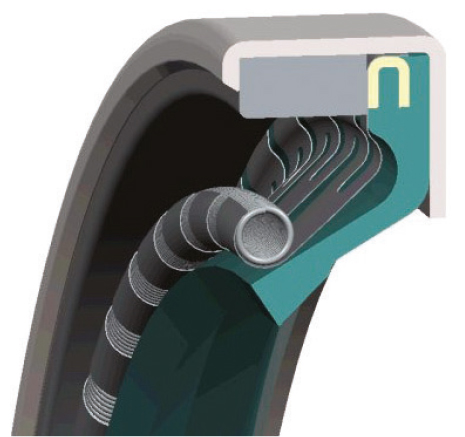

KLOZURE® Model 64

Garlock’s KLOZURE® 64 is specially designed for use in particularly difficult operating conditions. It has proven indispensable in the pulp and paper, aluminum and steel industries worldwide. KLOZURE® model 64 has proven its particular value in all applications involving large shaft-to-bore misalignment (STBM) and high peripheral speeds that still require high performance and reliability.

Features & Benefits

-

Heavy-duty metal outer case

-

Unique carrier/garter spring combination

Specifications

- Case: steel*

- Spring: Stainless steel garter and finger spring

- Shaft Diameters (mm): 203,2 – 1890,0

- Maximum Shaft Speed (m/s):

25,4

35,6 - Maximum Shaft Misalignment and Runout (mm):

3,18

2,36 - Available Lip Material:

MILL-RIGHT® N,

MILL-RIGHT® ES,

MILL-RIGHT® V,

Silicone

*other materials are available on request (Plunge grinding required).

KLOZURE® Oil Seals Rubber Backed

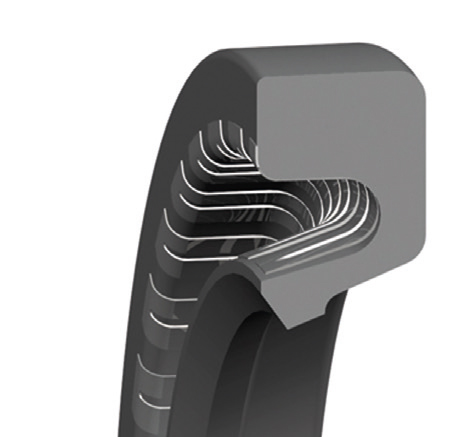

KLOZURE® Model 23

The original split seal has saved thousands of downtime hours. More than 300,000 sizes in Mill-Right® N.

(Requires a cover plate)

Features & Benefits

-

Cover plate required

-

Over 300,000 sizes readily available

Specifications

- Spring: Molded in stainless steel finger spring

- Shaft Diameters (mm): 76,2 – up

- Maximum Shaft Speed (m/s): 10,2

- Maximum Shaft Misalignment and Runout (mm): 0,25

- Available Lip Material:

MILL-RIGHT® N,

MILL-RIGHT® ES,

MILL-RIGHT® V,

Silicone

KLOZURE® Model 26

Versatile rubber O.D. seal, available in shaft sizes from 19 mm (0.750”) to 1524 mm (60”) in solid and split configurations.

(Split seal does not require a cover plate)

Features & Benefits

- Reverse bevel lip design prevents lip rollover

- Reinforced rubber OD

- Single and dual lip configurations available

Specifications

- Spring: Molded in stainless steel finger spring

- Shaft Diameters (mm): 19 – 1524

- Maximum Shaft Speed (m/s): 25,4

- Maximum Shaft Misalignment and Runout (mm): 0,38

- Available Lip Material:

MILL-RIGHT® N,

MILL-RIGHT® ES,

MILL-RIGHT® V,

NBR, HNBR, FKM

KLOZURE® Model 154

Single lip General Service oil seal. Captured garter spring prevents roll-out during installation. It is available in both split and solid configurations.

Features & Benefits

- Cover Plate Required

- General service seal

- Solid or split design (See configurations)

- Reinforced rubber OD

- Reverse bevel lip design prevents lip roll over

- Cover plate required (except for Model 154M)

Specifications

- Spring: Stainless steel garter spring

- Shaft Diameters (mm): 25,4 – up

- Maximum Shaft Speed (m/s): 15,2

- Maximum Shaft Misalignment and Runout (mm): 1,0

- Available Lip Material:

NBR, HNBR, FKM

(for 154-M and 154-ML please have a look at the catalogue)

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2023 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en