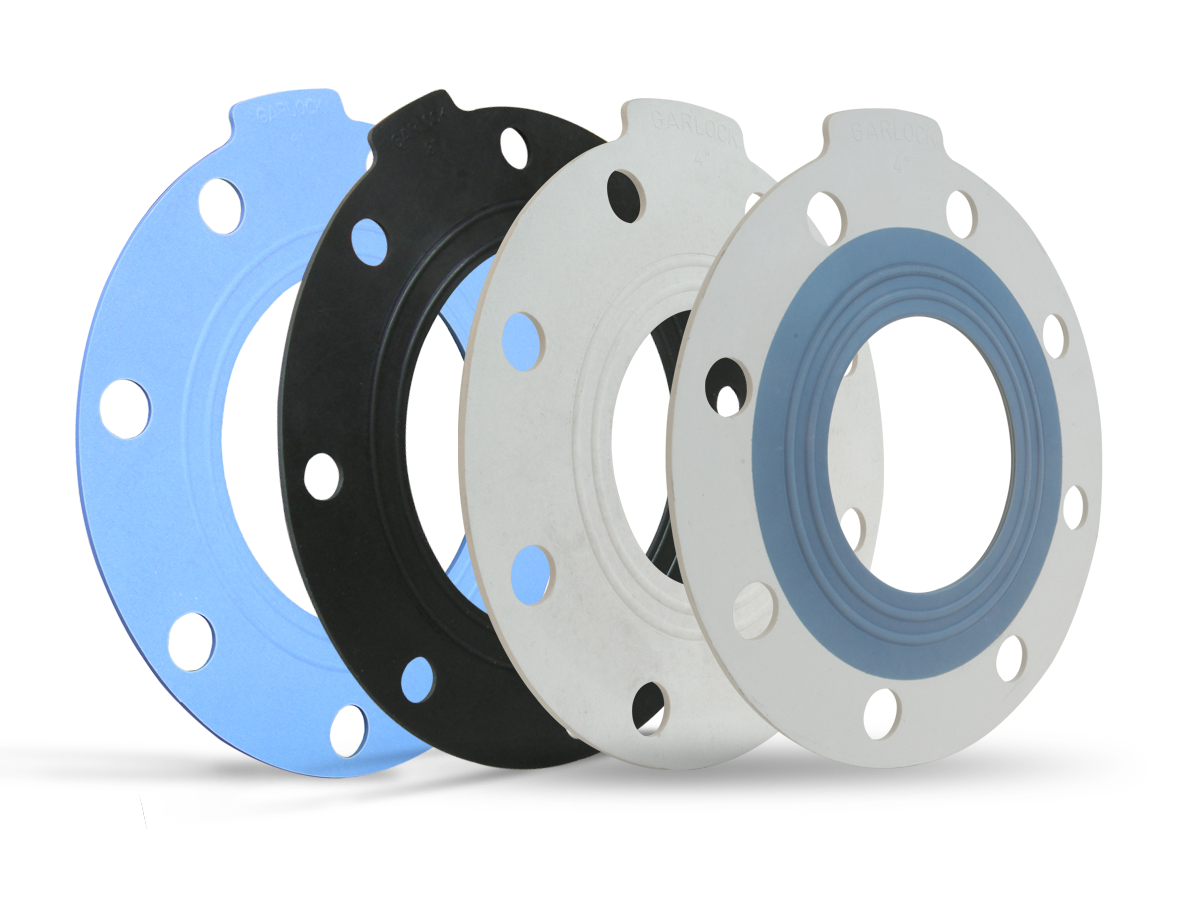

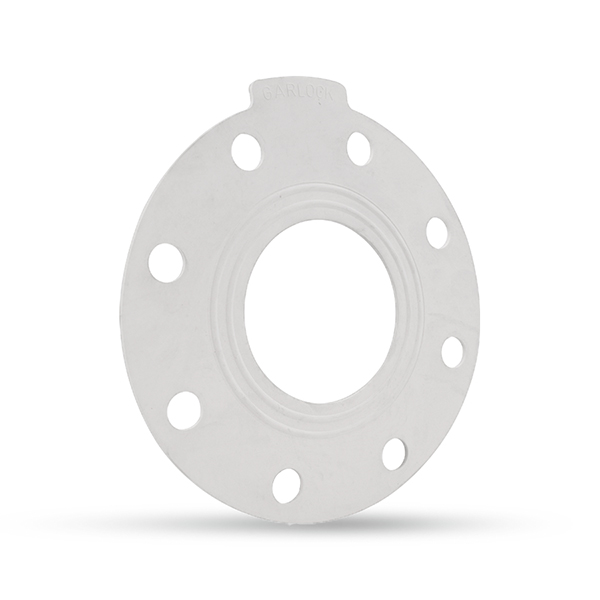

STRESS SAVER®

Low-Torque Gaskets

The Garlock STRESS SAVER® family of products feature molded, raised ribs that help to create a tighter seal by concentrating the compressive load, ideal for lightweight piping and non-metallic flange applications where low bolt load and chemical resistance are issues. This rib design allows the STRESS SAVER® gaskets to seal where flat rubber and traditional PTFE gaskets will not.

STRESS SAVER®

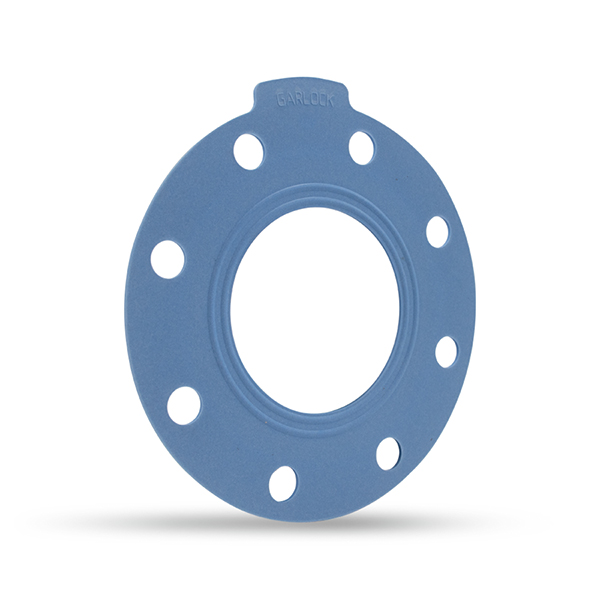

STRESS SAVER® GYLON® 3504

STRESS SAVER® GYLON® Style 3504 combines the proven sealing advantages of molded, raised ribs with the performance characteristics of the industry recognized GYLON® 3504 PTFE gasketing material. The combination of these two time-tested configurations makes STRESS SAVER® GYLON® Style 3504 the ultimate sealing solution. STRESS SAVER® GYLON® Style 3504 already has been tested in accordance to „new TA-Luft“ on some PP / PE / PVDF / FRP flange materials with backing steel backing flanges and A2-70 screws.

Features & Benefits

-

Chemical resistance – GYLON® 3504 is ideal for a wide range of caustics and acids, helping to simplify the selection process

-

Superior Physical Properties – Higher temperature and pressure capabilities as compared to rubber gaskets

-

Homogeneous Construction – Single piece design helps avoid permeation, delamination, fold-over of PTFE envelopes, or potential splitting when installed against raised face flanges

Specifications

- Composition:

100% GYLON® PTFE with aluminosilicate microspheres

- Color: Blue

- Temperature:

-268°C to 260°C / -450° F to 500° F

- Pressure:

55 bar, 800 psi

- PxT (max):

8.600 (bar x °C) / 250.000 (psig x °F)

- Media:

All solvents, most caustics and acids, hydrocarbons, refrigerants, cryogenics and potable water

- Approved to NSF-61 for potable water applications

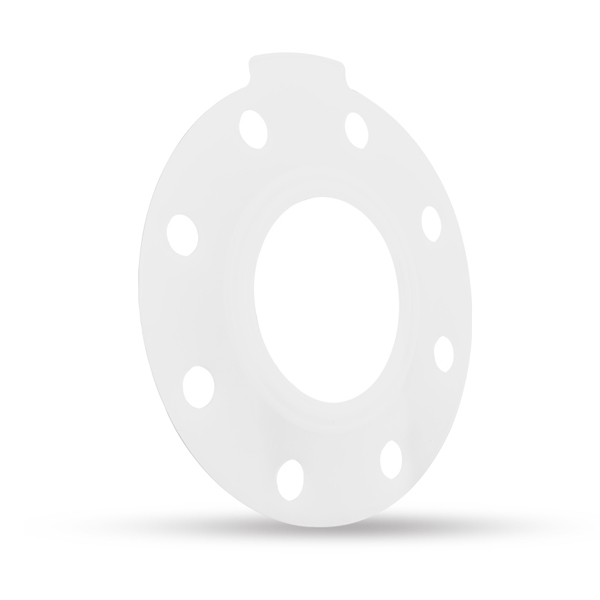

STRESS SAVER® 3522

Garlock’s patented STRESS SAVER® 3522 technology is constructed of 100% pure and restructured PTFE, offering universal chemical compatibility, limited leachable contaminants, and easy-to-clean contact surfaces with lowest surface energy which does not support bacterial growth. The STRESS SAVER® 3522 is engineered and designed to work effectively in higher-stress raised face flanges and lower-stress non-metallic flange designs to simplify the selection process and ensure long-term reliability.

Features & Benefits

-

Crush-resistant and ideal for both raised face and flat face flanges

- Easy-to-clean surface finish that does not promote bacterial growth

- Homogeneous construction to avoid permeation, delamination, or leachable contamination

Specifications

- Composition:

100% pure PTFE (No filler)

- Temperature:

-268°C to +260°C / -450° F to 500° F

- Pressure:

up to 83 bar

- Compressibility:

(ASTM F36) 20-25%

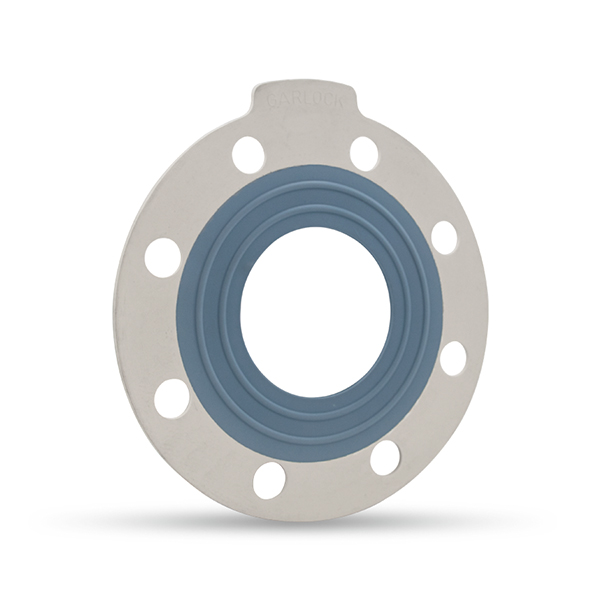

STRESS SAVER® 370

STRESS SAVER® 370 gaskets feature raised, molded-in sealing rings and seal with 75% less surface area for high performance in non-metallic flanges. Its pure PTFE sealing surface resists many chemicals and the contaminant-free EPDM body is ideal for a variety of high purity applications.

Features & Benefits

-

Raised, molded-in sealing rings seal with 75% less surface area for high performance in nonmetallic flanges

-

Proprietary process bonds PTFE to elastomer, won’t delaminate or leach

Specifications

- Available in ASME and DIN sizes

- Min. Temperature: -40°C / -40°F

- Max. Temperature: 149°C / 300°F

- Max. Pressure: 17 bar / 250 psi

- Maximum PxT 1/8: 1.717 (°C x bar) / 50.000 (°F x PSIG)

STRESS SAVER® XP

Single piece molded design made from high performance, proprietary blend of fluoroelastomers. Suitable for use in potable drinking water, steam, and severe chemicals.

Features & Benefits

-

Lower seating stress than expanded or specialty PTFE gaskets; ideal for nonmetallic flanges

-

Won’t fail due to filler attack

-

Eliminates envelope fold-over during installation

Specifications

- Min. Temperature:

-26°C / -15°F

- Max. Temperature:

204°C / 400°F

- Max. Pressure:

17 bar / 250 psi

- Maximum PxT ⅛:

1.717 (°C x bar) / 50.000 (°F x PSIG)

STRESS SAVER® 6800

The STRESS SAVER® Style 6800 provides an economical solution for applications where a PTFE envelope is not required.

Features & Benefits

-

Raised, molded-in sealing rings seal with 75% less surface area for high performance in nonmetallic flanges

-

More economical gasket where a PTFE envelope is not required

Specifications

- Min. Temperature:

-40°C / -40°F

- Max. Temperature:

149°C / 300°F

- Max. Pressure:

17 bar / 250 PSI

- Maximum PxT 1/8:

1.717 (°C x bar) / 50.000 (°F x PSIG)

Downloads

GYLON® Style 3504 & GYLON® Style 3522

- Declaration of Conformity FDA

- Letter of Conformance – Animal Derivates Ingredients – ADI

- Declaration of Conformity – Phthalate free, Bisphenol free

DIN EN 13555

FOOD SAFE – EC1935/2004, EC 10/2011 conformity

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2024 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en