THERMa-PUR®

Extreme Heat Gasket Material

Trusted for use in rocket boosters, THERMa-PUR ® takes on conditions that graphite cannot. This high-performance gasket material maintains an effective seal during pressure and temperature fluctuations, with excellent torque retention for lower leakage rates and less maintenance time.

THERMa-PUR ® is hydrophobic and resists water absorption and oxidation, keeping metallic gaskets in shape for a longer-lasting seal. When it’s time for removal, THERMa-PUR ® prevents gaskets from sticking to flanges, making removal easy and fast.

THERMa-PUR® Gaskets & Sheets

THERMa-PUR ®

Style 4122-FC Gasket Sheet

THERMa-PUR ® Style 4122 is designed for use in high temperature sealing applications. It is produced using an environmentally friendly solventfree process and combines a unique formulation with Garlock’s traditional quality. THERMa-PUR ® Sheet Material, available in a variety of sizes, is perfect for applications where extreme temperatures, oxidation, corrosion, and chemical compatibility are a concern.

Features & Benefits

- Extreme Temperature – Able to withstand high temperature, whether continuous or in thermal cycling conditions

- Chemical Resistance – Proprietary fomulation is resistant to a broad range of chemicals: Titanium Tetrachloride, molton salts and other heavy oxidizers

- Oxidation Resistance – Contains proprietary materials that provide improved weight loss characteristics over other high temperature solutions

- Hydrophobic (water resistant) – Resists water and provides electrical isolation thus reducing the possibility of corrosion between flanges made of dissimilar metals

- Easy Release from Flanges – Does not stick to flanges making removal of gaskets easy and fast

THERMa-PUR ®

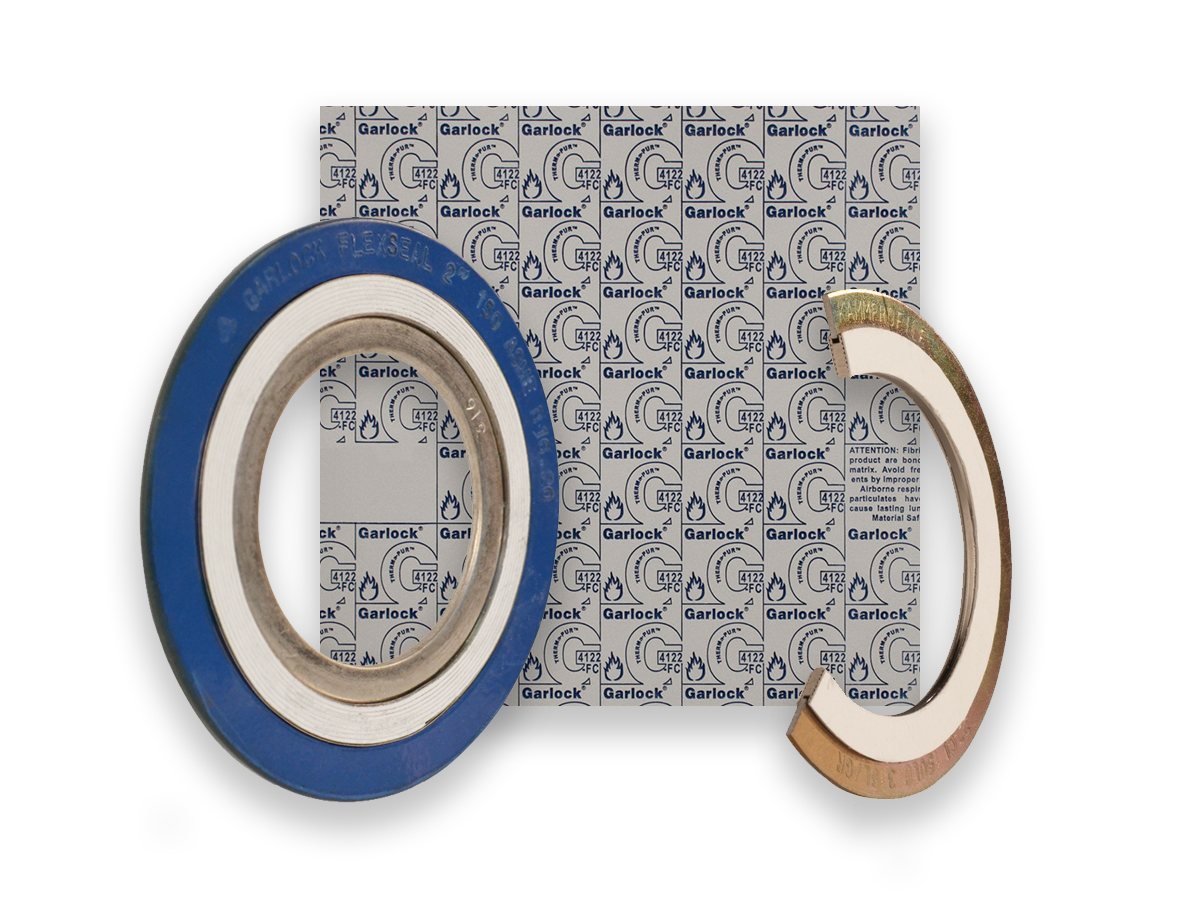

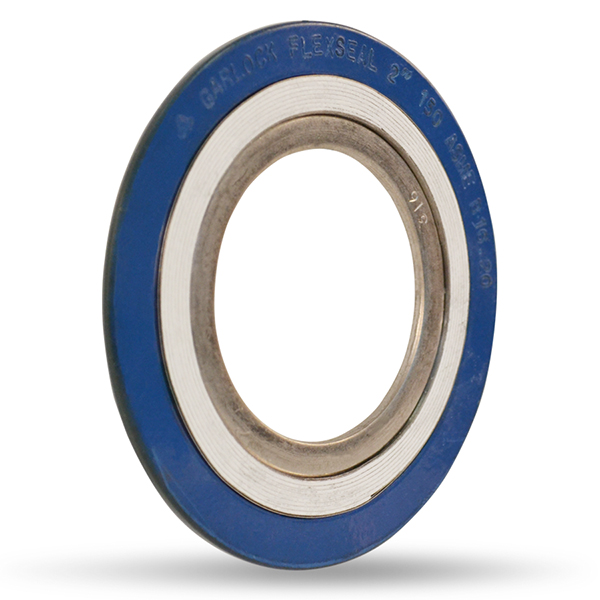

Spiral Wound Gasket (4122-SWG)

In addition to withstanding extreme high temperatures, Garlock’s Metal Gaskets featuring THERMa-PUR ® excel in highpressure and chemical exposure. Available in standard and custom configurations, these rugged metal gaskets accommodate many applications, including fire safe.

Features & Benefits

- Easy installation and removal

- Seals pressures to flange ratings, in accordance with ASME B16.5

- Suited to temperatures from cryogenic to 2000°F / 1093°C, depending on metal and filler

- Custom-tailored solutions accommodate a variety of conditions by combining various metals and filler materials

- Centering ring accurately locates the gasket on the flange face, provides additional radial strength, and acts as a compression limiter

- Spiral winding (sealing element) consists of preformed metal and soft filler material

- NOTE: Per ASME B16.20 all spiral wound gaskets for ASME B16.5 or B16.47 flanges are made with outer and inner rings (FLEXSEAL® RWI) unless specified by the customer at the time of order.

THERMa-PUR ®

4122-Kammprofile

Serrated solid metal core gasket with soft, deformable sealing material and integral outer ring.

Features & Benefits

- Seals less-than-perfect flanges to form a tight connection

- Performance replacement for jacketed heat exchanger gaskets

- Fire safe—passed API 6FB fire tests

- Solid metal core resists cold flow, over compression, and blowout

- Rigid core provides exceptional stability, even in large sizes, and facilitates handling and installation

- Available in wide variety of metals

- Seals under low stress—ideal for lighter weight flange designs

- Withstands extreme fluctuations in temperatures and pressures

THERPHONIC ® Style 4122-CMG

THERPHONIC ® Gaskets with a THERMa-PUR ® sealing element are an excellent choice for heat exchangers and low pressure applications also requiring high temperature. The corrugated metal core is completely encapsulated by the compressible sealing element.

Features & Benefits

- Accommodates a wide range of temperatures up to 1000°C / 1832°F

- Seals effectively during thermal cycling

- Fire safe – withstood API fire tests

- Chemically resistant

- Long service life

Downloads

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2024 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en