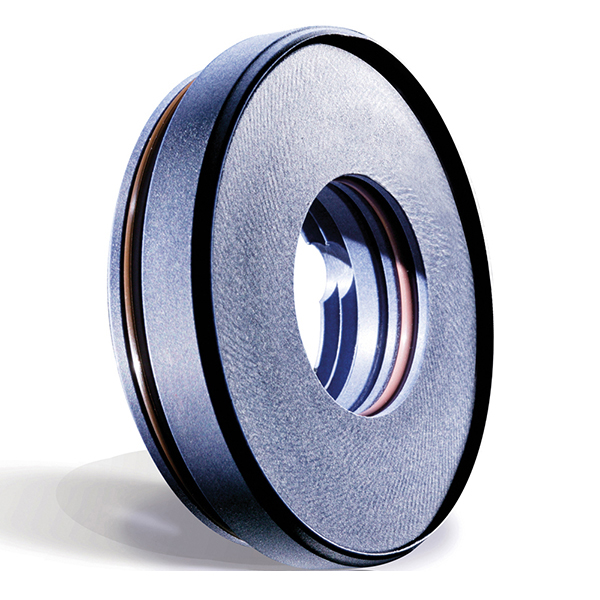

KLOZURE® Bearing Isolator

Bearing Protection

For maximum bearing life, KLOZURE® Bearing Isolator technology utilizes a non-contact seal design, eliminating shaft grooving while minimizing leakage and contamination ingress. KLOZURE® Bearing Isolator Labyrinth Seals provide ultimate performance and protection when uptime and reliability are critical concerns.

Commonly found in pumps, motors, and gearboxes, KLOZURE® Bearing Isolators feature a unitized labyrinth seal design to prevent ingress of contaminants and egress of lubrication. KLOZURE® Bearing Isolators utilize patented Cam-Lock O-ring grooves for ease of installation and retention.

GUARDIAN®

Bronze bearing isolator for non-flooded applications with patented cam-lock system and internal PFTE Unitizing Ring

feature. Surpasses all test requirements as specified by IEEE 841-2001.

Features & Benefits

-

Easy by hand installation — no need for an arbor press

-

Non-contact engineered labyrinth design reduces shaft drag. Uses less energy than contact lip seals

-

Lifetime bearing protection increases mean time between failure (MBTF)

-

Engineered labyrinth designs exclude contamination while retaining bearing lubrication, to IP 66 ratings

-

Eliminates repairs for shaft grooving

-

Lifetime bearing protection increases mean time between failure (MBTF)

-

Extended bearing life

-

Consistent sealing performance

-

Non-wearing components

-

Garlock’s patented Unitizing Ring eliminates metal to metal contact between stator and rotor.

ISO-GARD®

Unitized PTFE construction of this non contacting, two-piece seal provides excellent chemical and temperature resistance. The ideal alternative to lip seals in non-flooded, oil or grease applications.

Features & Benefits

-

Easy by-hand installation — no need for an arbor press

-

Uses less energy than contact lip seals

-

Compliant with safety and industry manufacturing standards

-

Non-contact engineered labyrinth design reduces shaft drag

-

Lifetime bearing protection increases mean time between failure (MBTF)

-

Extended bearing life

-

Consistent sealing performance

-

Non-wearing components

-

Engineered labyrinth designs exclude contamination while retaining bearing lubrication, to IP 55 ratings

-

Non-wearing components means seal properties are not degraded over time

-

Faster mean time to repair (MTTR) during rebuilds

-

Eliminates repairs for shaft grooving

-

Eliminates repairs for seal housings

Micro-Tec® II

Metallic bearing isolator with a built in air filter designed for applications that require bearing protection in highly contaminated environments. Utilizes microcellular technology to block out airborne contamination. Performance meets NEMA MG 1-2003 as required in IEEE 841-2001.

Features & Benefits

-

Easy by hand installation — no need for an arbor press

-

Uses less energy than contact lip seals

-

Non-contact engineered labyrinth design reduces shaft drag

-

Non-contact engineered labyrinth design reduces shaft drag

-

Eliminates repairs for shaft grooving

-

Extended bearing life

-

Consistent sealing performance

-

Non-wearing components

-

Garlock’s patented Unitizing Ring eliminates metal to metal contact between stator and rotor.

-

Engineered labyrinth designs exclude contamination while retaining bearing lubrication, to IP 66 ratings

SGi®

SGi® bearing isolators divert stray shaft current on electric motors driven by VFDs with an integrated AEGIS® Shaft Grounding Ring.

Features & Benefits

-

Uses less energy than contact lip seals

-

Compliant with safety and industry manufacturing standards

-

Engineered labyrinth designs exclude contamination while retaining bearing lubrication, to IP 66 ratings

-

Non-wearing components means seal properties are not degraded over time

-

Eliminates repairs for shaft grooving

-

Consistent sealing performance

-

Non-wearing components

-

Engineered labyrinth designs exclude contamination while retaining bearing lubrication, to IP 66 ratings

-

Non-wearing components means seal properties are not degraded over time

-

Faster mean time to repair (MTTR) during rebuilds

Downloads

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2024 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en