Blog

PS-SEAL® Non-Standard – dynamic seals in standard sizes with different lip configurations

The Garlock PS-SEAL® Standard is a PTFE-based high-performance seal that meets a wide range of requirements in practical use.

In some applications, however, the successful PS-SEAL® Standard proved not to be completely suitable. That’s why a team of Garlock experts developed additional designs: The PS-SEAL® Non-Standard.

With the PS-SEAL® Non-Standard, a range of variants is available. The variants are for application areas that require special configurations, since lip material and lip layout can be varied as desired.

The Garlock PS-SEAL® Non-Standard is known for reliable sealing of rotating shafts at high circumferential speeds, high pressures, and extreme temperatures from -90° to +260°C. The wide range of lip materials and layouts means the PS-SEAL® Non-Standard gives excellent sealing in difficult applications. The PS-SEAL® Non-Standard can handle PxV (Pressure x Velocity) of 45 bar.m/s for lubricated applications and 15 bar.m/s for dry running.

Furthermore, with the PS-SEAL® Non-Standard, Garlock offers a solution that fits into the small installation spaces of conventional shaft seals. Should none of the possible special configurations of PS-SEAL® Non-Standard prove to be suitable, the PS-SEAL® Special is available, with which almost all desired requirements can be achieved.

Be it several lips in a row, lips for media separation or a design with back to back lips – the PS-SEAL® Non-Standard offers a wide range of configuration options. In particular, the PS-SEAL® Non-Standard design with reverse lip is frequently used, and highly valued, in the food and pharmaceutical sectors.

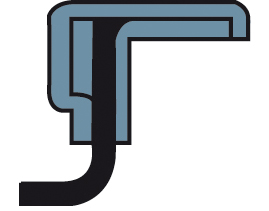

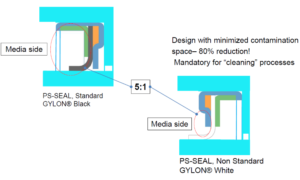

Reverse lip –

a single lip points out of the housing towards the media.

The success of this design is astounding:

The dead space is reduced by almost 80%, which has an extremely positive effect on cleaning and significantly reduces possible contamination. A clear plus in daily use.

Single lip with dust lip –

the seal lip sits in the housing as standard, and is supplemented by a dust lip facing towards the dry side.

If the working environment is contaminated with dust, the PS-SEAL® Non-Standard can also be equipped with a dust lip. Here, the suitability of the PS-SEAL® lips for dry running is particularly exploited, thus increasing the performance of the seal.

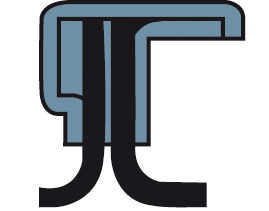

Back to back –

two lips seal equally on both sides.

Safe separation of two media is also possible – and this with only one seal. Where two shaft seals would otherwise have to be used back to back, this task is accomplished by a PS-SEAL® Non-Standard in back-to-back design – and with only the smallest installation width.

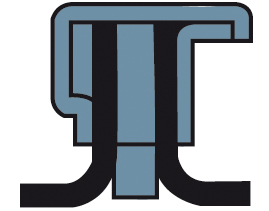

Tandem –

two seal lips towards the media.

If longer service life is required or if even greater plant safety is desired, a PS-SEAL® Non-Standard Tandem is a good choice. With the smallest installation width, two seal lips are now available instead of just one

Of course, the individual types of PS-SEAL® Non-Standard can also be combined with each other, thus offering every user an optimum range of sealing solutions.

If the versatile application range of PS-SEAL® Standard and PS-SEAL® Non-Standard does not represent the optimum solution, further variants are possible with PS-SEAL® Special on consultation with Garlock.

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2024 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en