Blog

Permanently avoid bearing damage due to liquid ingress and contamination in pumps, motors and gearboxes!

Lubricant contamination often leads to bearing damage in pumps, motors and gearboxes. A large proportion of contamination enters the bearing housings through gaps and openings. This occurs primarily at the points where shafts go through the bearing housings or at vent openings. In addition, temperature fluctuations during daytime and nighttime hours, as well as during operating and rest periods, cause vapours to expand and contract.

Lip seals usually cannot provide the performance and life required to protect bearings. Rotating labyrinth seals reduce lubricant contamination and the effects of pressure-induced alternating flows of contaminated ambient air.

A major advantage of labyrinth seals is that they are mostly wear-free and thus particularly durable. They also function safely and reliably: Moisture, dirt and dust get caught in the zigzag labyrinth paths of the seal due to flow resistance. Leaks, which can become a hazard to employees and the environment, are avoided.

The labyrinth profile consists of radial and axial spaces that give a recirculating effect during rotation, resulting in reliable protection. The labyrinth is constructed to give a non-contact seal without wear parts – for a long service life and with reduced drag on the shaft.

Typical applications for labyrinth seals include pump bearing frames, electric motors, gearbox housings, split pillow block bearings, fans, and turbines (steam).

Garlock offers a wide range of sizes and configurations (including customizable options) with KLOZURE® labyrinth seals. Installation requires no special tools. Their fluoroelastomer o-ring fit provides a static secondary seal that will not damage the shaft. KLOZURE® labyrinth seals’ uniform bi-directional seal design eliminates contamination.

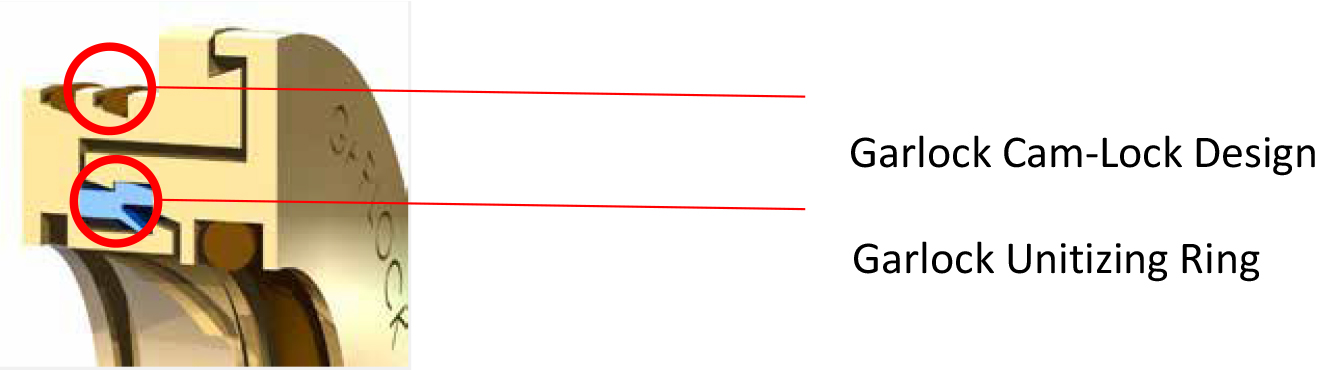

The Garlock Cam-Lock design provides superior retention force compared to standard bearing isolators. This Garlock design allows for easy installation by hand without the need for an arbor press or other tools.

The Garlock Unitizing Ring is a machined component with tight tolerances to maintain the labyrinth. This avoids internal metal-to-metal contact that creates metal chips that could damage the bearing.

The metallic Garlock KLOZURE® labyrinth seals are GUARDIAN®, Split GUARDIAN®, MICRO-TEC® II and SGi®. ISO-GARD® are non-metallic Garlock KLOZURE® labyrinth seals.

GUARDIAN® labyrinth seal are general-purpose seals designed to reduce downtime. The bi-directional seal provides both inlet and outlet protection. GUARDIAN® applications include auxiliary equipment in dirty, dusty, and wet environments. Split GUARDIAN® are fitted without dismantling the equipment. When uptime and mean time between repairs (MTTR) are critical, split seals are the right choice.

The MICRO-TEC® II series offer all the benefits of the GUARDIAN® range, plus microcellular foam (acting as an air filter) to trap all air contaminants.

The SGi® labyrinth seal has an integral AEGIS® shaft grounding ring to dissipate stray current on the shaft in electric motors driven by VFD (Variable Frequency Drive) that could introduce electrical discharges into the bearing.

The non-metallic ISO-GARD® labyrinth seal is made of a filled PTFE, providing excellent chemical compatibility. ISO-GARD® is suitable for rotating equipment with chemical cleaning, e.g. in the food and beverage industry.

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2024 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en