Blog

How to avoid bearing damage in rotating applications that require the use of aggressive chemicals.

Moisture, dust, and dirt are just a few examples of contaminants that can enter a bearing housing. Contamination causes a number of problems including seal degradation. The result: leakage, which poses a significant safety risk to employees and the environment. Labyrinth seals provide a remedy here. They are low-wear and reliable in use.

But what to do in rotating applications that require the use of aggressive chemicals?

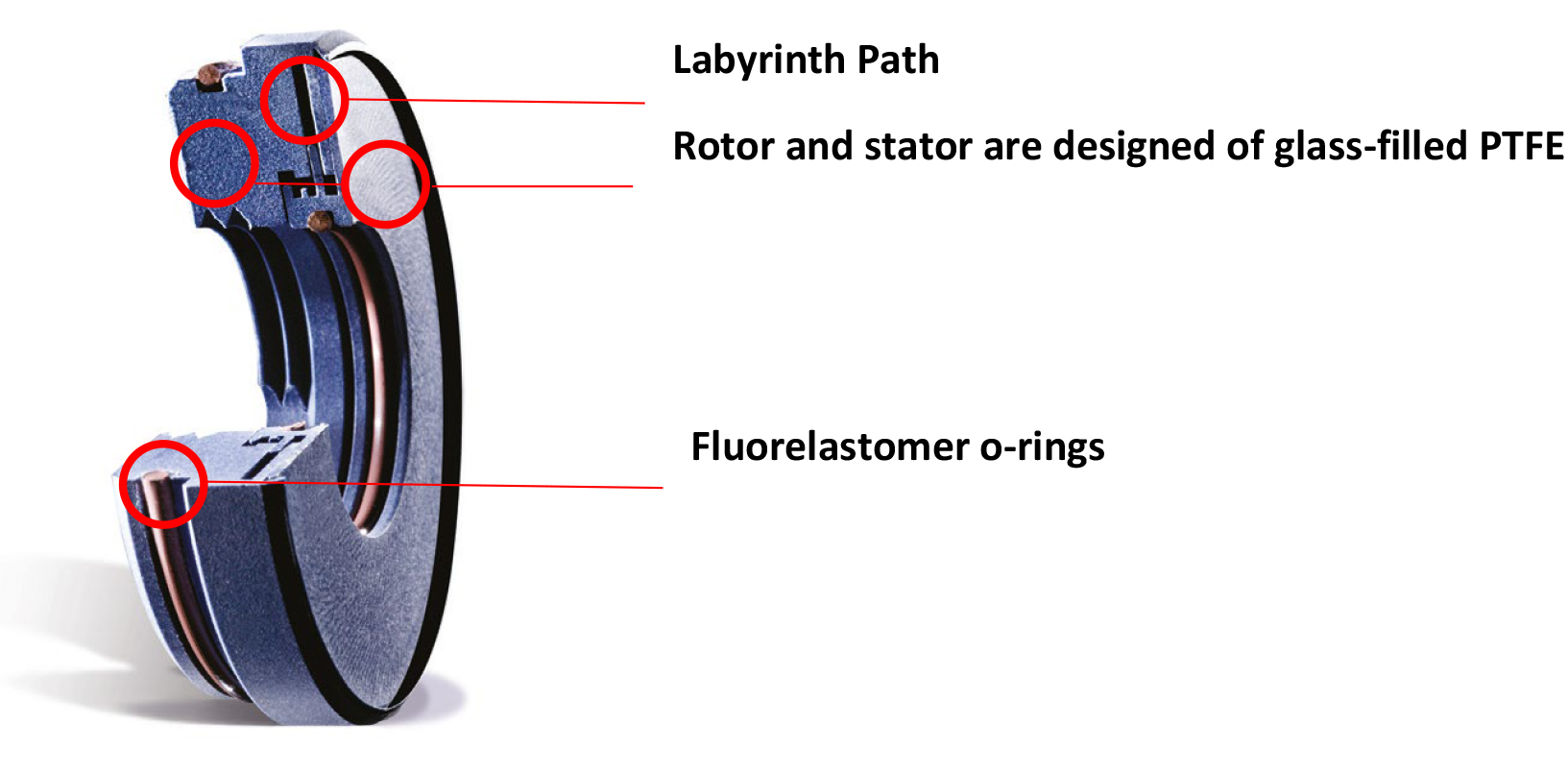

The Garlock non-metallic labyrinth seal ISO-GARD® is ideally suited for these applications due to a special combination of materials. Both the rotor and the stator of the ISO-GARD® are made of glass-filled PTFE. The tortuous labyrinth passage inside the ISO-GARD® prevents foreign matter from entering the housing. Fluoroelastomer o-rings on the rotor and stator, ensure the best compression for optimal sealing. FDA compliant o-rings are also available on request.

Applications for ISO-GARD® include food and beverage industries and also in the paper manufacturing (“black liquor” applications).

The benefits at a glance:

- Filled PTFE construction provides excellent chemical compatibility

- Unitized construction will not come apart during installation

- Meets IEEE 841 Test Standard

- Meets NEMA MG-1

- Available in a broad range of configurations

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2024 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en